Delving into the intricate world of tattooing, this comprehensive guide unveils the inner workings of rotary tattoo machines through a detailed rotary tattoo machine parts diagram. Each component, from the frame to the needle bar, is meticulously examined, providing a thorough understanding of their functions and significance.

Unveiling the intricacies of rotary tattoo machines, this guide delves into the materials, designs, and specifications that define their performance and ergonomics. From the power supply to the maintenance protocols, every aspect is explored to empower tattoo artists with the knowledge they need to optimize their craft.

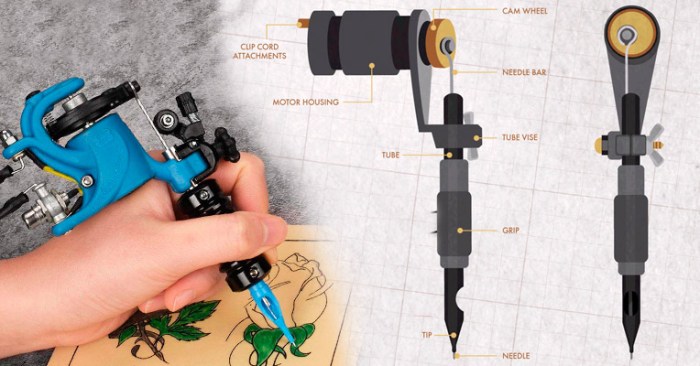

Machine Components Diagram: Rotary Tattoo Machine Parts Diagram

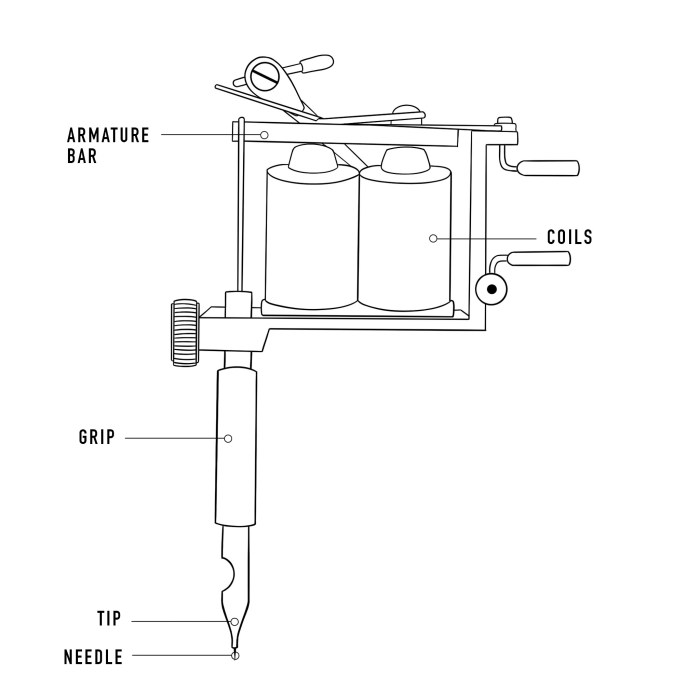

The rotary tattoo machine, a crucial tool for tattoo artists, comprises several essential components that work together to deliver precise and efficient tattooing. Understanding these components is fundamental for both tattooists and those interested in the mechanics of tattooing.

The diagram below presents a labeled illustration of the primary components of a rotary tattoo machine:

Frame, Rotary tattoo machine parts diagram

The frame serves as the foundation of the tattoo machine, housing and supporting the other components. It provides structural stability and ensures proper alignment and functionality of the machine.

Motor

The motor is the driving force of the tattoo machine, converting electrical energy into mechanical energy. It rotates the drive shaft, which in turn drives the needle bar and needle.

Drive Shaft

The drive shaft is a rotating component that transmits power from the motor to the needle bar. It is typically made of a durable material, such as stainless steel, to withstand the high-speed rotation.

Needle Bar

The needle bar is a slender, elongated component that holds the tattoo needle. It moves up and down, driven by the drive shaft, to puncture the skin and deposit ink.

Other Essential Parts

- Grips:The grips provide a comfortable and secure hold for the tattoo artist, allowing for precise control and maneuverability of the machine.

- Needles:The needles are the essential components that penetrate the skin and deposit ink. They come in various sizes and configurations to suit different tattooing styles and techniques.

- Power Supply:The power supply provides the electrical power to the motor, allowing the tattoo machine to operate.

Frame Design and Materials

The frame of a rotary tattoo machine is a critical component that houses and supports the internal mechanism. Different materials are used for rotary tattoo machine frames, each with its own advantages and disadvantages.

Material Selection

The choice of material for a rotary tattoo machine frame primarily depends on factors such as durability, weight, and cost. Common materials include:

- Aluminum:Aluminum is a lightweight and durable material that is commonly used in tattoo machine frames. It is resistant to corrosion and can be anodized to create a variety of colors. However, aluminum can be more expensive than other materials.

- Steel:Steel is a strong and durable material that is often used in heavy-duty tattoo machines. It is more resistant to wear and tear than aluminum but is also heavier.

- Composite Materials:Composite materials, such as carbon fiber or fiberglass, are lightweight and strong. They offer a combination of durability and flexibility, making them suitable for high-performance tattoo machines.

Ergonomic Design

In addition to material selection, the ergonomic design of the rotary tattoo machine frame is also important. A well-designed frame should fit comfortably in the artist’s hand and provide a stable platform for tattooing. Features such as finger grips, contoured edges, and adjustable angles can enhance the ergonomics of the machine.

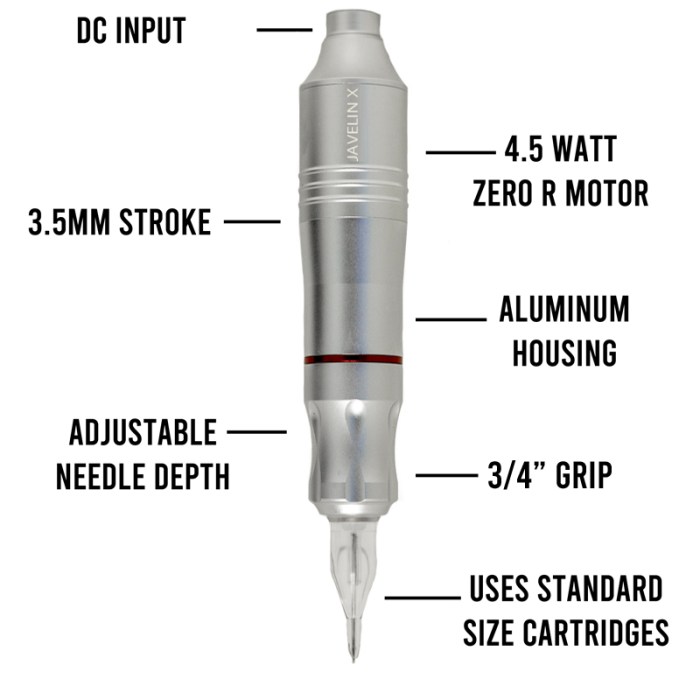

Motor Types and Specifications

The type of motor used in a rotary tattoo machine significantly impacts its performance. Rotary tattoo machines employ various motor types, each with unique characteristics and specifications.

To understand how motor characteristics affect machine performance, we must first examine the different types of motors commonly found in rotary tattoo machines.

Brushed DC Motors

- Simple and cost-effective design.

- Generate sparks during operation, requiring regular maintenance.

- Lower torque and speed compared to brushless motors.

Brushless DC Motors

- No sparking during operation, reducing maintenance requirements.

- Higher torque and speed than brushed motors.

- More expensive and complex design.

Stepper Motors

- Precise control over speed and torque.

- Generate heat during operation, requiring cooling systems.

- Limited speed range compared to DC motors.

| Motor Type | Speed | Torque | Power Consumption |

|---|---|---|---|

| Brushed DC | Lower | Lower | Higher |

| Brushless DC | Higher | Higher | Lower |

| Stepper | Limited | Precise | Variable |

Drive Shaft and Eccentric System

The drive shaft and eccentric system are crucial components of a rotary tattoo machine. The drive shaft rotates, and an eccentric cam is attached to it, which converts the rotary motion into an up-and-down motion of the needle.The eccentricity of the drive shaft refers to the distance between the center of the shaft and the center of the eccentric cam.

This eccentricity directly affects the needle stroke length. A greater eccentricity results in a longer stroke length, allowing for deeper penetration of the needle into the skin.There are various types of drive shaft and eccentric system designs. Some common types include:

Direct Drive System

In a direct drive system, the drive shaft is directly connected to the eccentric cam. This design provides a precise and efficient transfer of power from the motor to the needle, resulting in consistent and reliable performance.

Belt Drive System

In a belt drive system, a belt is used to connect the drive shaft to the eccentric cam. This design allows for greater flexibility in positioning the motor and the eccentric system, providing more options for machine configuration.

Gear Drive System

In a gear drive system, gears are used to connect the drive shaft to the eccentric cam. This design offers high torque transmission and can handle higher loads, making it suitable for heavy-duty tattooing.

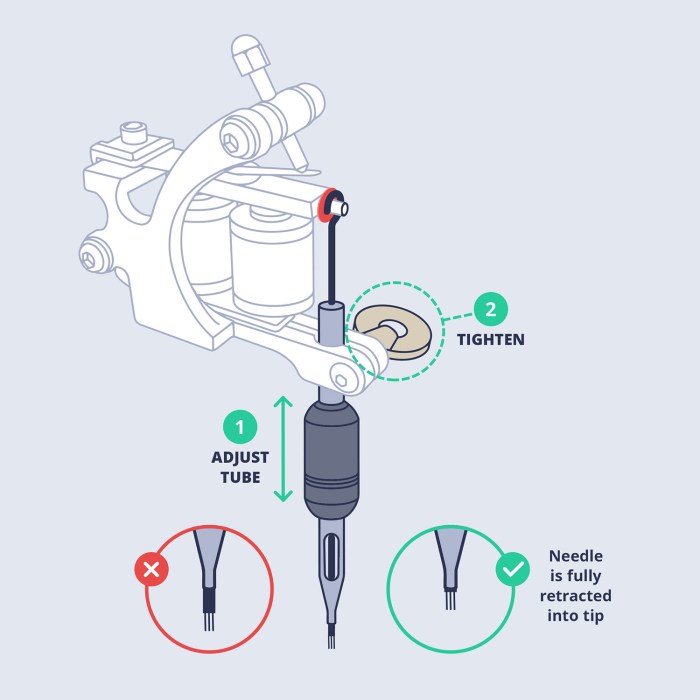

Needle Bar and Cartridge System

The needle bar in a rotary tattoo machine serves as the intermediary between the motor and the needle cartridge, facilitating the precise and controlled movement of the needles during the tattooing process. It is typically constructed from lightweight, durable materials such as aluminum or stainless steel, ensuring both longevity and efficient operation.

Needle Cartridges

Needle cartridges come in various configurations, each designed for specific tattooing styles and techniques. They consist of a group of needles arranged in a predetermined pattern and secured within a disposable housing. Rotary machines are compatible with a wide range of cartridge types, including round liners, shaders, magnums, and flats, allowing artists to customize their setups based on the desired effect.

Choosing the Right System

Selecting the appropriate needle bar and cartridge system depends on several factors, including the tattooing style, desired line width, and depth of penetration. Round liners are suitable for precise lines, while shaders create soft, blended areas. Magnums and flats are ideal for larger areas and shading, respectively.

The size and configuration of the needles within the cartridge also influence the resulting line thickness and saturation.

Power Supply and Voltage Regulation

The power supply in a rotary tattoo machine is responsible for providing the electrical energy needed to operate the motor and drive the needle. It also regulates the voltage supplied to the motor, which affects the speed and power of the machine.

There are different types of power supplies available, each with its own features and capabilities. Some of the most common types include:

AC/DC Power Supplies

- AC power supplies convert alternating current (AC) from a wall outlet into direct current (DC) that can be used by the tattoo machine.

- DC power supplies provide a constant voltage output, which is more stable than the voltage from an AC power supply.

Analog Power Supplies

- Analog power supplies use a dial or knob to adjust the voltage output.

- They are less precise than digital power supplies, but they are also less expensive.

Digital Power Supplies

- Digital power supplies use a digital display to show the voltage output.

- They are more precise than analog power supplies, and they often have additional features, such as presets and memory functions.

Voltage regulation is an important aspect of power supply design. The voltage supplied to the motor affects the speed and power of the machine. A higher voltage will result in a faster and more powerful machine, while a lower voltage will result in a slower and less powerful machine.

It is important to choose a power supply that is compatible with the tattoo machine being used. Using an incompatible power supply can damage the machine or cause it to operate improperly.

Maintenance and Troubleshooting

Maintaining a rotary tattoo machine is crucial to ensure optimal performance and longevity. Regular cleaning, lubrication, and troubleshooting can prevent issues and keep the machine functioning smoothly.

Maintenance Guide

- Clean the machine regularly:Use a soft cloth or brush to remove ink and debris from the exterior and internal components. Avoid using harsh chemicals or abrasive materials.

- Lubricate the machine:Apply a small amount of lubricant to the moving parts, such as the drive shaft and eccentric system, to reduce friction and wear.

- Inspect the needle bar and cartridge system:Check the needle bar for damage or bending, and replace the cartridge if it shows signs of wear or clogging.

- Check the power supply and voltage regulation:Ensure the power supply is providing the correct voltage and amperage for the machine’s operation.

Troubleshooting Common Issues

- Machine not starting:Check the power supply, connections, and voltage regulation. If the machine still doesn’t start, it may require professional repair.

- Machine running too fast or slow:Adjust the voltage or power supply settings. If the issue persists, check the drive shaft and eccentric system for proper alignment.

- Machine vibrating excessively:Inspect the frame and components for any loose connections or damaged parts. Balance the machine by adjusting the eccentric system.

- Needle skipping or stuttering:Check the needle bar and cartridge for damage or misalignment. Replace the cartridge if necessary.

Answers to Common Questions

What are the key components of a rotary tattoo machine?

The primary components of a rotary tattoo machine include the frame, motor, drive shaft, needle bar, and power supply.

What factors should be considered when choosing a rotary tattoo machine?

When selecting a rotary tattoo machine, consider factors such as the frame material, motor specifications, drive shaft design, needle bar compatibility, and power supply features.

How does the drive shaft affect the performance of a rotary tattoo machine?

The eccentricity of the drive shaft determines the needle stroke length, influencing the depth and precision of the tattoo.